Lotoke Titaniuml Alloy Butterfly Valve Technical Manual

| Fabrication |

Titanium equipment is often used in severe corrosive environments encountered in the chemical processing industries.Titanium has been considered an exotic "wonder metal" by many. This was particularly true in reference to castings.However, increasing demands and rapidly advancing technology have permitted titanium castings to be commercially available at an economical cost. The combination of its cost, strength, corrosion resistance, and service life in very demanding corrosive environments suggest its selection in applications where titanium castings have never been considered in the past.

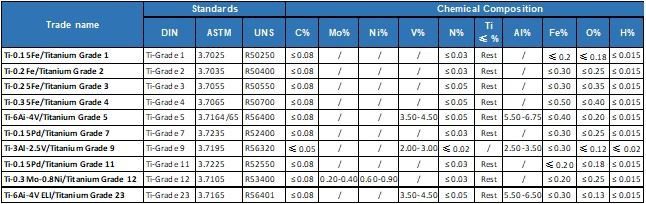

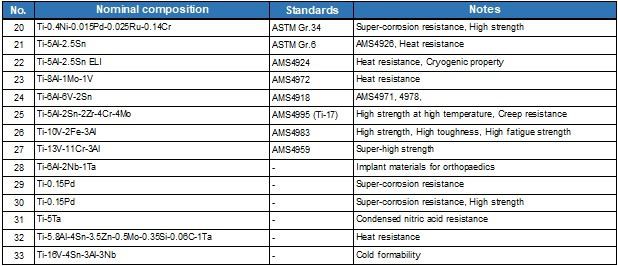

| Standards And Composition |

| Machineability |

Titanium castings can be machined as readily as stainless steels by following well established practices and procedures. Titanium is less prone to work hardening than austenitic stainless steels but has low heat conductivity, resulting in higher temperatures on the cutting edge of the tool. Consequently, tool life is relatively short. Basic knowledge and understanding of machining procedures combined with a little practice will provide satisfactory results. Care must be taken to minimize very fine chips since they are pyrophoric (i.e., may spontaneously ignite in the presence of air).

| Weldability |

Anyone capable of welding stainless steels can weld titanium as long as certain precautions are observed. These include: an inert gas welding process; protection from the atmosphere; and non-coated electrodes. Titanium, being a reactive metal, has an extremely high affinity for oxygen and nitrogen (it acts as a blotter for these elements) and absorption of even small quantities of these elements will embrittle a weld severely. Though titanium is easily welded, the "secret" of welding is cleanliness and ingenuity exercised in protecting the weldment from the atmosphere. A guide to indicate the acceptability of a titanium weldment is its color. A silvery appearance is indicative of a well protected, ductile weldment; a straw or light yellow through light blue color signals a slight amount of contamination, but normally an insufficient quantity to be damaging; and a dark blue through purple or the formation of a white powdery substance indicates contamination to the extent of serious embrittlement.

CP titanium is readily weldable using GTAW (gas tungsten arc welding) or TIG (tungsten inert gas) processes if adequate shielding is provided using pure inert gas (argon or helium). Use of a trailing shield is recommended. Titanium must be free of oil, grease or other contamination before welding. Preheat or post-heat are not required. Friction welding, laser welding, resistance welding, plasma arc welding, electron beam welding, and diffusion bonding can also be used.

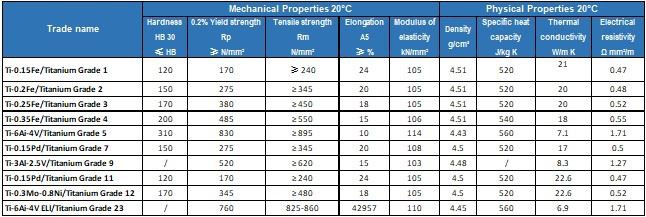

| Mechanical And Physical Properties |

| Mechanical Properties Chart 1 |

Commercially pure titanium has a tensile strength ranging from 275 to 590 MPa, and this strength is controlled primarily through oxygen content and iron content. The higher the oxygen and iron content, the higher the strength. We are currently producing various titanium alloys from Ti-3A1-2.5V with a tensile strength of 620 MPa, to Ti-15Mo-5Zr-3AI with a tensile strength of 1250 MPa.

(Tensile strengths listed above are TIPBV's specified minimum values.)Fig.1 shows the tensile strength and yield strength of commercially pure titanium and various titanium alloys and Table 1 shows the tensile characteristics of commercially pure titanium and representative titanium alloys. The specific strength of titanium alloy is superior to other metallic materials in the temperature range up to 600ûC. (Fig. 2)

| High Temperature Characteristics |

Commercially pure titanium is stable for use in the temperature range up to approximately 300ûC due to its specific strength, creep resistance, and other properties. On the other hand, titanium alloys exhibit high strength in the temperature range up to approximately 500ûC. (Fig. 3)

| Low Temperature Characteristics |

Neither commercially pure titanium nor titanium alloys become brittle even at extremely low temperatures. In particular, commercially pure titanium and Ti-5A1-2.5Sn EL1 can be used even at 4.2 K (-269 degree ). (Fig. 4)

| Fatigue Characteristics |

The fatigue strength (107 cycles) is roughly equivalent to 50 percent of the tensile strength, and welding does not cause a significant decline in fatigue strength. (Figs. 5 and 6) In addition, even in seawater, both commercially pure titanium and titanium alloys exhibit almost no decline in fatigue strength.

| Toughness |

The fracture toughness of titanium alloys range from 28 to 108MPa.m1/2 and is in negative correlation with tensile yield strength. Fracture toughness is dependent on microstructure, and thus fracture toughness is higher in materials with acicular structures.

| Formability |

Titanium is readily formed at room temperature, using techniques and equipment suitable for steel. When correct parameters have been established, tolerances similar to those attainable with stainless steel are possible with titanium and its alloys. Three factors make forming of titanium somewhat different from forming of other metals.

1. The room temperature ductility of titanium, as measured by uniform elongation, may be less than that of other common structural metals. This means that titanium may require more generous bend radii and has lower stretch formability.

2. The modulus of elasticity of titanium is about half that of steel. This causes significant spring back after forming titanium for which compensation must be made.

3. The galling tendency of titanium is greater than that of stainless steel. This necessitates close attention to lubrication in any forming operation in which titanium is in contact (particularly moving contact) with metal dies or other forming equipment.

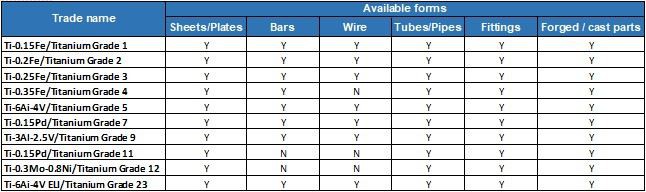

The various grades of ATI unalloyed titanium exhibit differences in formability. Grades 1, 11 and 17 titanium, which are the softest and most ductile grades, exhibit the greatest formability. The slightly greater strengths of Grades 2, 7 and 16 titanium are still quite formable, but less so than Grades 1, 11 or 17. The higher strength of Grade 4 titanium makes it the least formable of the CP titanium alloys.

Normally, titanium surfaces are acceptable for forming operations as received from the mill. Gouges and other surface marks introduced during handling should be removed by sanding. To prevent edge cracking, burred and sharp edges should be filed smooth before forming.

| Avaiable Forms |

| Corrosion Resistance |

General Corrosion

Titanium has excellent resistance to corrosion in a wide variety of environments including seawater, salt brines, inorganic salts, bleaches, wet chlorine, alkaline solutions, oxidizing acids, and organic acids. Titanium is incompatible with fluorides, strong reducing acids, very strong caustic solutions, and anhydrous chlorine. Due to its combustibility, titanium is Corrosion-Resistant Titanium not suitable for pure oxygen service. Titanium does not release any toxic ions into aqueous solutions, thus helping to prevent pollution.

Crevice Corrosion

Titanium has excellent resistance to crevice corrosion in salt solutions and generally outperforms stainless steels. Unalloyed CP titanium (grades 1, 2, 3, and 4) typically do not suffer crevice corrosion at temperatures below 80 degree (175 degree F) at any pH. Palladium alloyed CP titanium (grades 7, 11, 16 and 17) are more resistant and typically do not suffer crevice corrosion at temperatures below 250 degree (480 degree F) at pH greater than 1.

Microbiologically Influenced Corrosion (MIC)

Titanium appears to be immune to MIC. They do suffer biofouling, but this can be controlled by chlorination (which does not impair titanium).

Galvanic Corrosion

Although it is a reactive metal, due to the extreme stability of the passive film which forms on its surface, titanium typically exhibits noble behavior. Thus it functions as the cathode when coupled with other metals. Titanium is not affected by galvanic corrosion, but can accelerate corrosion of other metals.

Stress Corrosion Cracking

Titanium has excellent resistance to stress corrosion cracking in hot chloride salt solutions.

Erosion Corrosion

Titanium exhibits excellent resistance to flow-induced and erosion corrosion at velocities to above 40 m/sec.

Hydrogen Embrittlement

Titanium is susceptible to hydrogen embrittlement under some circumstances. This is generally less of a problem for the low- strength grade 1 and grade 2 titanium alloys than for higher strength titanium alloys. Absorption of hydrogen by titanium normally occurs when the temperature is above 80 degree (175 degree F), and the titanium is galvanically coupled to an active metal or an impressed current or the pH is less than 3 or greater than 12.

| Typical Applications |

Applications for corrosion resistance use normally CP-Ti (ASTMGrades 1, 2, 3, 4), which are good corrosion resistant but low strengthmaterials.These are used in tanks, heat exchangers, reactor vessels, etc., respectively for chemical-processing, desalination and power generation plants. For some corrosion applications, ASTM Grades 7, 8, and 11 are used. Inmedicine field, Grade 2 is usually used in low-strength applications, whereas Grade 5 (Ti-6Al-4V) is employed usually in applications requiring higher strength.

Applications for high-strength performance use high-strength titanium alloys such as Ti-6Al-4V, Ti-8Al-1Mo-1V, Ti-6Al-2Sn-4Zr-2Mo, Ti-6Al-6V-2Sn, Ti-10V-2Fe-3Al, among others, but the Ti-6Al-4V alloy is unique because it merges a set of interesting properties, good workability and production experience, and high commercial availability.Therefore, this alloywas converted into the standard against which other alloysmust be compared when selecting titanium alloys for specific applications.

Heat Transfer

A major industrial application for titanium is in heat transfer applications for which the cooling medium is seawater, brackish water or polluted water. Titanium condensers, shell and tube heat exchangers, and plate and frame heat exchangers are used extensively in power plants, refineries, air conditioning systems, chemical plants, offshore platforms, surface ships and submarines.

Millions of feet of welded titanium tubing are in power plant condenser service, and there have been no reported failures due to corrosion on the cooling water side.

DSA-Dimensional Stable Anodes

The unique electrochemical properties of the titanium DSA make it the most energy efficient unit for the production of chlorine, chlorate and hypochlorite.

Desalination

Its excellent resistance to corrosion, erosion, and high condensation efficiency make titanium the cost-effective and dependable material for critical segments of desalination plants. Increased usage of very thin walled welded tubing makes titanium competitive with copper-nickel.

Extraction and Electro-Winning of Metals

Hydrometallurgical extraction of metals from ores in titanium reactors is an environmentally friendly alternative to smelting processes. Extended lifespan, increased energy efficiency, and greater product purity are factors promoting the usage of titanium electrodes in electro-winning and electro-refining of metals like copper, gold, manganese and manganese dioxide.

Medical

Titanium is widely used for implants, surgical devices, pacemaker cases and centrifuges. Titanium is the most biocompatible of all metals due to its resistance to attack by body fluids, its high strength and its low modulus.

Hydrocarbon Processing

The need for longer equipment life, coupled with requirements for less downtime and maintenance, favor the use of titanium in heat exchangers, vessels, columns and piping systems in refineries, LNG plants and offshore platforms. Titanium is immune to general attack and stress corrosion cracking by hydrocarbons, hydrogen sulfide, brines and carbon dioxide.

Marine Applications

Because of high toughness, high strength and exceptional erosion/corrosion resistance, titanium is currently being used for submarine ball valves, fire pumps, heat exchangers, castings, hull material for deep sea submersibles, water jet propulsion systems, shipboard cooling and piping systems.

Chemical Processing

Titanium vessels, heat exchangers, tanks, agitators, coolers, and piping systems are utilized in the processing of aggressive compounds, like nitric acid, organic acids, chlorine dioxide, inhibited reducing acids and hydrogen sulfide.

Structural/Architectural Applications

Titanium's use as an architectural material is rapidly gaining worldwide acceptance. Its corrosion resistance, light weight, strength, durability, soft metallic appearance, and almost unlimited life span give titanium a cost-effective edge over other materials. Typical areas include roofs, ceilings, exterior wall panels, sculptures and monuments.

| Available Products |

Butterfly Valve Standard Production Range | |||

ANSI Class 150 | ANSI Class 300 | ANSI Class 600 | |

Rating-Psi | 285 | 740 | 1440 |

Rating-Bar | 20 | 50 | 100 |

Size-Inch | 2-60 | 2-48 | 2-24 |

Size-mm | DN50-DN1500 | DN50-DN1200 | DN50-DN600 |

TESTING Testing | API 598 | ||

Face To Face Specification | ANSI B16.10 / API 609 / MSS-SP-68 / ISO 5752 | ||

End Flange Specifications | ASME B16.5: Class 150, 300, 600 DIN ISO PN10, PN16, PN25, PN40 | ||

Connection | Wafer, Lugged, Double Flanged | ||

Actuaror-Manual | Lever Handle, Worm Gear Operator | ||

Actuator-Automatic | Electric Motor, Pneumatic Double Acting, Pneumatic Spring Return | ||

تگ های محبوب: lotoke titaniuml alloy butterfly valve technical manual, China, manufacturers, factory, customized, wholesale, price, cheap, in stock, for sale, free sample

ارسال درخواست